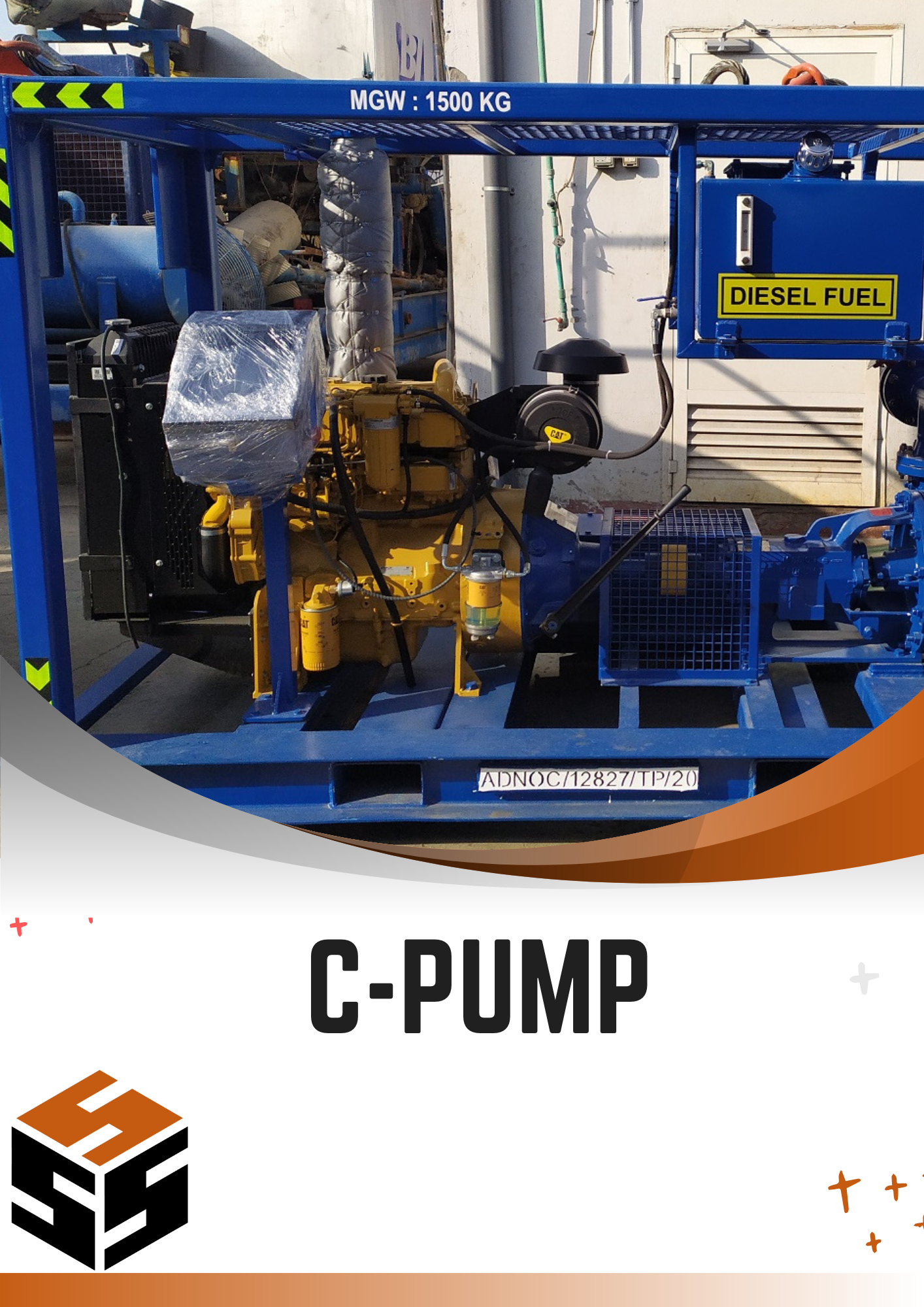

C-Pump is a type of centrifugal pump that is used to move liquids, such as water, chemicals, and petroleum products, in various industries, such as oil and gas, chemical processing, and wastewater treatment. Centrifugal pumps work by converting the kinetic energy of a rotating impeller into potential energy to move the fluid through the pump.

C-Pump is a unique type of centrifugal pump that uses a curved blade impeller, which allows it to operate at high efficiencies and with low vibration and noise levels. The C-Pump design also includes a volute casing and diffuser, which helps to reduce energy losses and optimize flow characteristics.

Some benefits of C-Pump include:

Energy-efficient: C-Pump operates at high efficiencies, which can result in significant energy savings over time.

Low noise and vibration: C-Pump has a low noise and vibration level, which makes it suitable for use in noise-sensitive environments.

Easy maintenance: C-Pump has a simple design that makes it easy to disassemble and clean.

Wide range of applications: C-Pump can be used to pump a wide range of liquids, including abrasive, viscous, and shear-sensitive fluids.

Proper selection, installation, and maintenance of C-Pump is important to ensure safe and efficient operation. The pump should be selected based on the fluid being pumped, the flow rate required, and the pressure and temperature of the system. The pump should be installed according to manufacturer instructions and checked regularly for leaks, wear, and other signs of damage. Additionally, regular maintenance and inspection should be performed to ensure that the pump is in good working condition and that any issues are addressed promptly.